Application

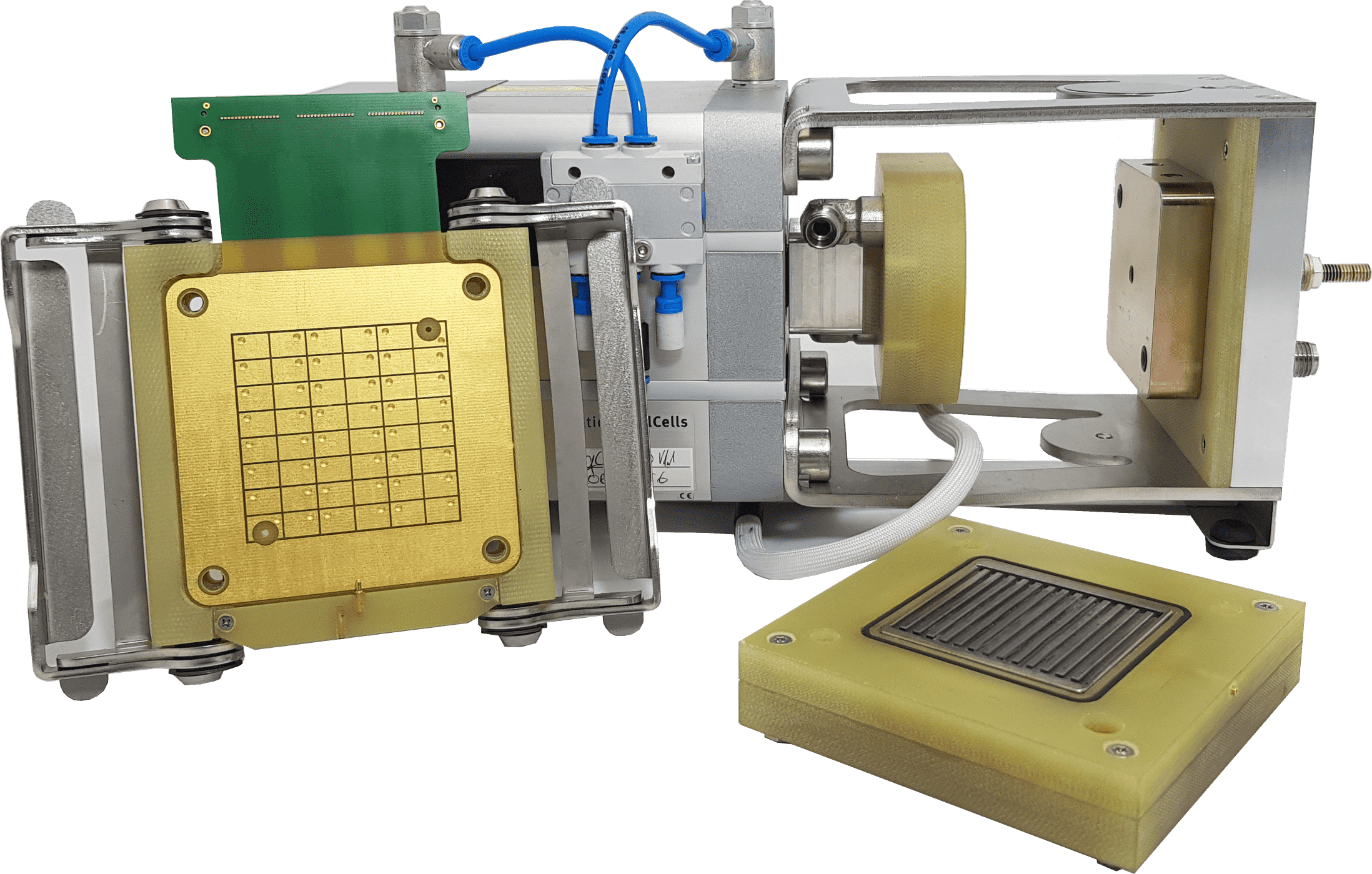

Measure current density and temperature distribution within the cell over the active cell area. With the baltic quickCONNECTfixture from the company balticFuelCells GmbH.

- Analysis of bipolar plates (flow field design), membrane electrode assemblies (MEA) and grouting concepts

- Evaluation of operating strategies and aging effects.

- Life cycle test on fuel cells, electrolyzers and redox flow batteries

- Can be combined with electronic impedance spectroscopy (1D model to 2D model)

Specifications

The DiLiCo current density product series offers a completely new price level for current density, temperature and cell voltage measurement for the baltic quickCONNECT fixture FC25/100 and FC50/125 thanks to a new, proprietary measurement method. The three variants of the measurement system offer optimal prerequisites for use in various applications. Whether high current densities (DiLiCo CUSTOM) or high temperatures (DiLiCo HIGH TEMP), DiLiCo offers the right measurement system for both measurement conditions. The third variant (DiLiCo CURR TEMP) offers the possibility to determine both current density and temperature distributions inexpensively and precisely. All meters in this product line feature additionally an integrated cell voltage measurement. Optional up to five temperature sensors for the media circuits can be connected for each variant of the measuring system.

.

DiLiCo current density consists of a segmented sensor layer consisting of current and temperature sensors, electronics for evaluating and transmitting the measured data to the customer's computer, and optionally, software for visualization and extensive evaluation of the measured values for current density (current strength related to area) and temperature. The segmented sensor layer is integrated between two cells, without direct contact to the gases and liquids. Each segment measures the current and temperature for a portion of the active area of the membrane electrode assembly. The area of all segments is equal to the area of the active reaction surface of the membrane.

.

As a result, DiLiCo current density reveals a two-dimensional image of the distribution of current density and temperature over the area of the membrane-electrode unit. The activity of the membrane, the design of bipolar plates, seals, and other components can thus be evaluated both in operation but also out of operation. During operation, conditions such as gas undersupply, thermal hot spots, and flooding can be identified, directly measure and visualize the correlations between humidification systems and cell performance, and measure the effects of one-dimensional imprinting of AC components by electrochemical impedance spectroscopy on two-dimensional measurement by DiLiCo current density closer to the active area of the cell.

Delivery

- DiLiCo current density sensorlayer

- Evaluation electric with software

- External power supply

- Instructions

User

- User of the baltic quickCONNECT fixture FC25/100 and FC50/125

Deutsch

Deutsch